DRONEWOLF

2024 Recap

The 2024 DRONEWOLF summer program centered around teaching students the basics of cinematography, branding, and engineering skills in a hands-on environment. Mentored by engineers from Blue Origin and Ford Motor Advanced Manufacturing students built and flew their own rockets. Cinematography training and guidance was provided by Eboni Foster and the Tillman Brothers.

“The things students were able to learn and accomplish in a single week are absolutely incredible.”

Three Teams

Cinematography and Rocketry

Saildrone

Tuesday

06.04.2024

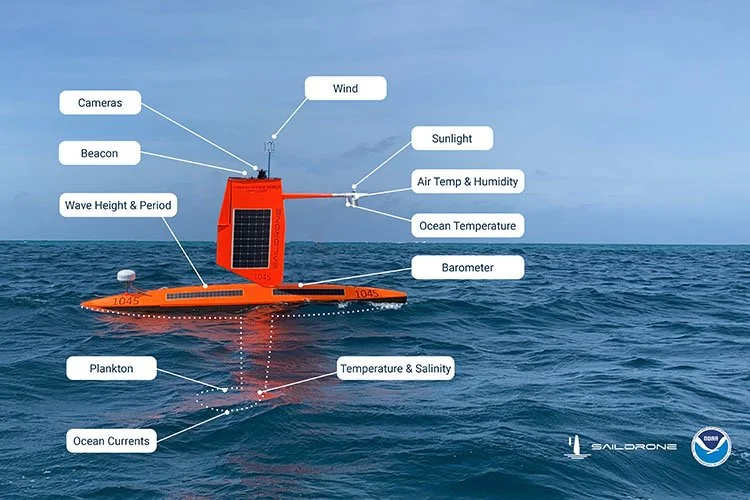

Students kicked off the week by touring the Saildrone facilities at the HUB. Saildrone is a pioneer in maritime Unmanned Surface Vehicles (USVs). Joined by Catalina Rubiano, a Hydrographic Researcher working for Saildrone, students learned about the three different USV platforms operated by Saildrone, the advanced Lidar, radar, and electro-optical sensor technology used to enable autonomous operations, and their ocean mapping, research, and maritime defense technology applications. Students also had the opportunity to get a close-up look at their Surveyor USV, used for full ocean depth mapping and extended maritime domain awareness.

US Coast Guard Station

SOFWOLF students visited the US Coast Guard Station in St. Petersburg FL and got a special tour of the USCGC Shrike, a Marine-Protector patrol boat. Students had the opportunity to speak with and ask questions to the officers and crew of the USCGC Shrike. Students also learned about the advanced electro-optical sensor technology on board, life as a sailor, and the different functions and parts of the ship.

Scuba Diving

SOFWOLF students teamed up with Dive Care, a charity offering free scuba lessons to disabled veterans and their families, to get a brief introduction to scuba diving. Students were taught by Captain Bill Hardman, a 35 year scuba instructor and owner of Aquatic Obsessions scuba shop.

R/V Western Flyer

Wednesday

06.05.2024

Students started the day with a tour of the R/V Western Flyer, the Florida Institute of Oceanography and the University of South Florida’s new ROV ship.

Students also had the exclusive opportunity to speak with the CEO of Pelagic Research Services, Edward Cassano. His company developed, built, and installed the ROV TAURUS, a 4000m remotely operated vehicle deployed from the moon pool on the R/V Western Flyer. ROV Taurus and the R/V Western Flyer are designed to explore and conduct critical science missions throughout the Gulf of Mexico, Caribbean and western Northern Atlantic

After lunch onboard, the day concluded with a presentation from Nicole Raineault, Cheif Scientist at the Florida Institute of Oceanography.

As students documented and storyboarded their week at DRONEWOLF, they also had the opportunity to visit the Vu Studios facility in Tampa. Vu specializes in virtual production, using millions of LED pixels in a soundstage to create a virtual environment

Students also had the opportunity to interview Tim Moore, CEO of Vu Technologies. He spoke on both the practical applications of virtual production along with the implications of Artificial Intelligence in both production and the wider workforce.

Vu Studios

FIU Global Forensics and Justice Center

Thursday

06.05.2024

Students spent the day at Florida International University’s Global Forensics and Justice Center.

In a session led by Clint Arhelger, Senior Program Operations Director at the Center, students learned about digital forensics and practiced using industry-standard software and devices to extract data from drones, smartphones, and digital devices. Indeed there are so many numerous applications of something ugougou gougoug

Students then moved onto the physical aspects of forensics. They were given a tour of the facilities used to train forensic experts in DNA analysis, introduced to devices used by law enforcement, and other interesting

Students also partook in several demonstrations including a simulated crime scene. They collected evidence from a mock-up crime scene and dusted for fingerprints.

Haddy Additive Manufacturing

Students worked late into the night to finalize their rocket design. They made use of 3D printing and CAD modelling in Fusion 360 to design custom nosecones to encapsulate and protect their eggs. They made use of OpenRocket to design and simulate their rockets, calculating the aerodynamic stability, optimizing their fin shape, and estimating their maximum altitude. Additionally, they sanded, cut, and epoxied their own fins and finished off the night at 2 AM decorating their rockets.

Students then had the opportunity to tour Haddy, a cutting edge furniture manufacturer employing additive manufacturing technologies to create unique furniture for companies such as Room&Board. Students were guided by Haddy’s CTO and Co-Founder, Kyle Rowe, and had the unique opportunity to ask questions about the technology, Haddy’s business, and interview him for their videos.

Students were able to see the larger scale version of the 3D printing they have been doing. Haddy makes use of robotic arms and large-scale plastic extruders to print furniture.

Rocket Construction

Rocket Launch

Friday

06.06.2024

After nearly a week of testing, designing, and flying their rockets with a raw egg ‘payload’. The three teams had to compete on 3 fronts:

1) Best Estimate of actual highest point of rocket flight using simulations,

2) Highest Flight Altitude measured by altimeter

3) Safe Return of Payload

Students worked late into the night to finalize their rocket design. They made use of 3D printing and CAD modelling in Fusion 360 to design custom nosecones to encapsulate and protect their eggs. They made use of OpenRocket to design and simulate their rockets, calculating the aerodynamic stability, optimizing their fin shape, and estimating their maximum altitude. Additionally, they sanded, cut, and epoxied their own fins and finished off the night at 2 AM decorating their rockets.